Polyiso Insulation Thickness R-Value Chart: Understanding R-Value

When it comes to building energy-efficient homes or commercial properties, insulation plays a crucial role in keeping the structure comfortable, reducing energy costs, and maintaining durability. One of the most popular and effective insulation types used in roofing and wall systems is polyisocyanurate insulation, commonly known as polyiso.

But to make the most informed decisions when selecting polyiso insulation, it’s essential to understand R-value—the metric used to gauge thermal resistance. In this comprehensive guide, we’ll dive deep into how polyiso insulation works, break down its R-value based on thickness, and explain how you can use this information to improve energy performance in your building.

What Is Polyiso Insulation?

Polyisocyanurate, or polyiso, is a rigid foam board insulation that is often used in commercial roofing systems, residential walls, and ceilings. It’s made from a closed-cell foam plastic that offers superior thermal resistance compared to many other insulation materials.

Key Benefits of Polyiso:

- High R-value per inch

- Lightweight and easy to install

- Moisture-resistant

- Fire retardant properties

- Environmentally friendly (often contains recycled materials)

Because of its high performance and low environmental impact, polyiso is commonly chosen for projects aiming to meet LEED certification standards and other energy efficiency goals.

What Is R-Value and Why Does It Matter?

The R-value is a measure of thermal resistance—how well a material resists the conductive flow of heat. The higher the R-value, the greater the insulation performance. R-values are essential when selecting materials for:

- Residential homes

- Commercial properties

- Roofing systems

- Basement and attic insulation

- Wall cavities

Factors Affecting R-Value:

- Material type – Polyiso has a higher R-value per inch compared to materials like fiberglass or EPS.

- Density – Denser materials often provide more resistance to heat flow.

- Installation quality – Gaps, compression, or improper placement can reduce actual performance.

- Moisture – Wet insulation loses effectiveness.

Understanding the relationship between insulation thickness and R-value is key to designing high-performance buildings.

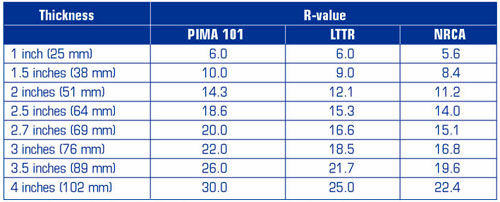

Polyiso Insulation Thickness vs. R-Value Chart

Below is a general R-value chart for polyiso insulation, assuming average industry values at 75°F mean temperature. (Note: Specific products may vary slightly depending on brand and manufacturing standards.)

| Thickness (inches) | R-Value (Approx.) |

|---|---|

| 0.5” | R-3.2 to R-3.4 |

| 1.0” | R-6.0 to R-6.5 |

| 1.5” | R-9.0 to R-9.8 |

| 2.0” | R-12.0 to R-13.0 |

| 2.5” | R-15.0 to R-16.3 |

| 3.0” | R-18.0 to R-19.5 |

| 3.5” | R-21.0 to R-23.0 |

| 4.0” | R-24.0 to R-26.0 |

Important Notes:

- Polyiso generally provides R-6 to R-6.5 per inch, which is one of the highest among foam board insulations.

- The chart above is based on LTTR (Long-Term Thermal Resistance) testing, which better represents how insulation performs over time.

How Polyiso Stacks Up Against Other Insulations

Let’s compare polyiso to other common insulation materials based on R-value per inch:

| Material | R-Value per Inch |

|---|---|

| Polyiso | 6.0 – 6.5 |

| Extruded Polystyrene (XPS) | 5.0 |

| Expanded Polystyrene (EPS) | 3.6 – 4.2 |

| Fiberglass Batts | 2.9 – 3.8 |

| Mineral Wool | 3.0 – 3.3 |

| Spray Foam (Closed Cell) | 6.5 – 7.0 |

Polyiso stands out as a top performer in the rigid foam category, offering great thermal performance with less thickness, which can be beneficial in roofing applications or wall assemblies where space is limited.

Applications of Polyiso Insulation

1. Commercial Roofing Systems

Polyiso is the go-to choice for low-slope commercial roofing systems, often used under single-ply membranes like TPO, EPDM, or PVC. Benefits include:

- High thermal resistance

- Lightweight properties

- Fire resistance

- Compatibility with multiple membrane types

2. Residential Wall Assemblies

Polyiso is increasingly used in continuous insulation (CI) on the exterior of walls. This method reduces thermal bridging and significantly increases whole-wall R-values.

3. Ceilings and Attics

Because of its high R-value per inch, polyiso is ideal for attics or ceiling spaces with limited height. This helps achieve desired R-values without sacrificing space.

4. Green Buildings and LEED Projects

Many polyiso products contain recycled content and contribute to green building credits. Its performance and sustainability profile make it an excellent choice for eco-conscious builders.

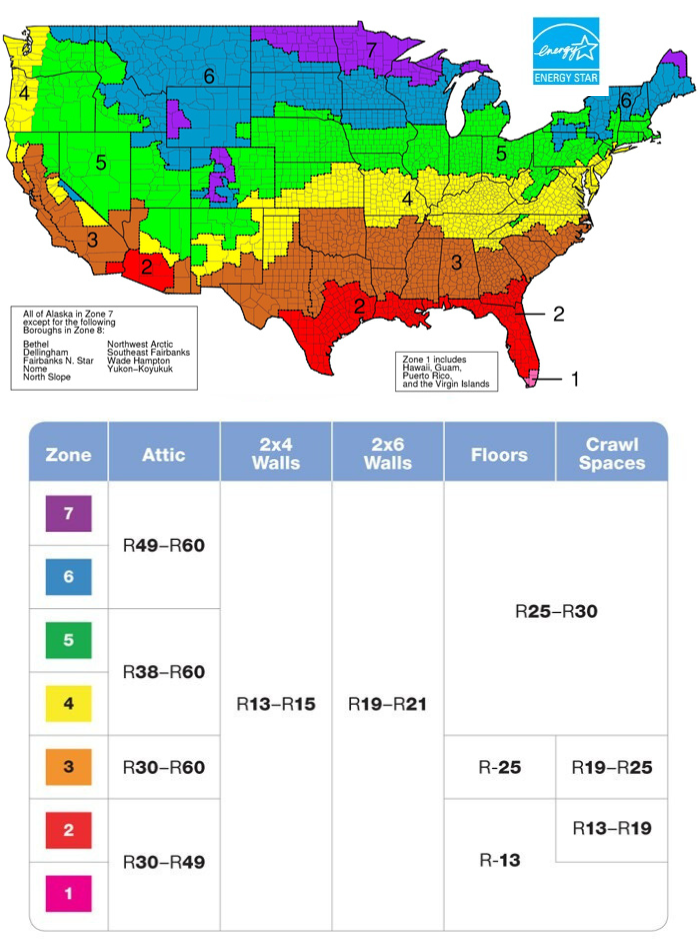

How Much Insulation Do You Need?

Your ideal insulation level depends on your climate zone, building type, and specific energy goals. Below is a simplified guide for roof insulation R-values by U.S. climate zones (per IECC guidelines):

| Climate Zone | Roof R-Value (Minimum) |

|---|---|

| 1–2 | R-30 |

| 3 | R-38 |

| 4 | R-49 |

| 5–6 | R-49 to R-60 |

| 7–8 | R-60+ |

For wall applications using polyiso as continuous insulation, codes generally recommend R-5 to R-10 depending on the zone and assembly type.

Tips for Installing Polyiso Insulation

✅ Plan for Proper Fastening

Polyiso boards must be properly secured to the roof deck or wall substrate using mechanical fasteners or approved adhesives. Improper installation can create gaps and reduce thermal performance.

✅ Use Tape for Seams

Sealing all joints with insulation tape or flashing prevents air infiltration and improves the system’s air barrier.

✅ Layering for High R-Values

Multiple thinner boards can be layered together to meet higher R-value targets while reducing thermal bridging and avoiding overly thick panels.

✅ Account for Thermal Drift

Over time, polyiso may experience slight thermal drift, meaning the R-value can decrease slightly. Always choose LTTR-tested products and consider future performance in your calculations.

Common Questions About Polyiso and R-Values

1. Does polyiso lose R-value over time?

Yes, polyiso can experience a small loss in R-value due to off-gassing of blowing agents—a phenomenon known as thermal drift. However, modern manufacturing and LTTR testing standards account for this, giving you a more accurate long-term performance value.

2. Is polyiso insulation water-resistant?

Polyiso has a closed-cell structure, which resists moisture penetration. However, it can still absorb water at the seams if not properly sealed. Foil-faced polyiso boards offer improved moisture and vapor resistance.

3. Can polyiso be used in below-grade applications?

Polyiso is not recommended for use below grade (i.e., in foundation walls or under slabs) because prolonged exposure to ground moisture can degrade performance.

4. What’s the difference between faced and unfaced polyiso?

Faced polyiso includes a layer of foil or fiberglass, improving fire performance, moisture resistance, and radiant heat reflectivity. Unfaced boards are typically used in specific roof assemblies or where other barriers are used.

Why R-Value Isn’t Everything

While R-value is a critical metric, it’s just one part of the equation. Whole-wall and whole-roof performance also depend on:

- Air sealing

- Moisture control

- Thermal bridging

- Installation quality

Using polyiso insulation in conjunction with continuous air barriers, vapor retarders, and proper flashing ensures the system performs as designed.

Final Thoughts: Choosing the Right Polyiso Thickness and R-Value

When selecting polyiso insulation for your roofing or wall project, consider:

- Your local building code R-value requirements

- Space constraints (thicker insulation = more depth)

- Climate zone

- Long-term performance expectations

- Budget vs. energy savings

The polyiso insulation thickness to R-value chart should serve as a reliable reference to help match your design goals with actual product specifications.

If you’re working with a contractor or architect, make sure they specify LTTR-rated polyiso products and install them correctly for maximum effectiveness.

Need Help With Roofing Insulation?

At S&K Construction and Remodeling LLC, we specialize in residential and commercial roofing systems throughout Youngstown, Cleveland, Medina, Beachwood, and surrounding Northeast Ohio areas. As an Owens Corning Preferred Contractor, we use only the best materials—including high-performance polyiso insulation—to deliver energy-efficient, durable, and code-compliant roofing systems.

We offer free estimates, financing options, and expert guidance to help you meet your energy efficiency goals. Check out our 5-star Google reviews to see why customers trust us for quality craftsmanship and reliable service.

Let’s Talk Insulation!

Want help determining the right insulation for your next roofing project? Contact S&K Construction and Remodeling LLC today to schedule a free consultation. Our team can walk you through product options, R-value targets, and full-system design for maximum performance.

📞 Call us now at 440.235.3124

🌐 Visit us at www.skroofingandconstruction.com

S&K Construction and Remodeling LLC – Your local experts in roofing, siding, insulation, and remodeling!

(440) 307-2060

(440) 307-2060