What Is Apron Flashing? A Complete Homeowner’s Guide

If you’re learning about roofing and waterproofing systems, you may have come across the term apron flashing. You might be wondering, what is apron flashing and why is it so important to a house? Apron flashing is a type of roofing material, usually made of metal, that is used to prevent water from leaking into vulnerable areas where the roof meets walls, chimneys, dormers, or other vertical structures. It acts as a protective barrier, directing rainwater away from seams and gaps that could otherwise allow moisture to penetrate. Without proper apron flashing, even the best roof can eventually develop leaks, mold, or structural damage.

In this detailed guide, we’ll dive deep into everything you need to know about apron flashing: how it works, why it matters, where it’s installed, the different materials available, installation techniques, common mistakes, maintenance tips, and how it compares to other flashing types. By the end, you’ll have a complete understanding of this essential roofing component.

Chapter 1: Understanding the Basics of Apron Flashing

1.1 What Does Apron Flashing Do?

The primary role of apron flashing is to redirect water away from roof penetrations or vertical surfaces. When water flows down the roof and meets an obstruction such as a chimney or a dormer wall, it tends to pool or seep into tiny cracks. Apron flashing creates a sloped, watertight transition that sends water safely onto the roof surface, where it can continue toward gutters and downspouts.

1.2 Where Is Apron Flashing Used?

Common locations include:

- Chimneys – Along the bottom edge where the chimney meets the roof.

- Dormers – At the base of a dormer where it connects with the roof.

- Walls or step-ups – Where a roof slope intersects with a vertical wall.

- Roof-to-wall transitions – Any point where horizontal and vertical planes meet.

Without flashing, these joints would be weak spots highly vulnerable to leaks.

Chapter 2: The Importance of Apron Flashing

2.1 Preventing Water Intrusion

Roofs are constantly exposed to rain, snow, and wind. Even tiny gaps can allow water to creep beneath shingles, eventually causing wood rot, insulation damage, and interior leaks. Apron flashing acts like armor, sealing the most vulnerable points.

2.2 Extending Roof Lifespan

By keeping water out, apron flashing reduces the risk of structural damage and prolongs the overall life of your roof system.

2.3 Protecting Interior Spaces

Without proper flashing, leaks often show up inside the home as water stains on ceilings or walls. Over time, this can lead to expensive repairs, mold growth, and even health concerns.

2.4 Aesthetic Value

In addition to being functional, properly installed apron flashing blends seamlessly with the roof, helping maintain a neat, finished look around chimneys, dormers, and walls.

Chapter 3: Materials Used for Apron Flashing

Apron flashing can be made from a variety of materials. Each has its strengths and trade-offs:

- Galvanized Steel – Affordable, durable, and commonly used in residential roofing.

- Aluminum – Lightweight, easy to shape, and resistant to rust, though it may corrode when in contact with certain woods or concrete.

- Copper – Extremely long-lasting and attractive, but significantly more expensive.

- Lead – Traditionally used, flexible, and durable, though less common today due to environmental concerns.

- PVC or Synthetic Materials – Sometimes used in specialty applications but not as long-lasting as metal.

Choosing the right material often depends on budget, local climate, and roof design.

Chapter 4: How Apron Flashing Is Installed

4.1 The General Process

Installing apron flashing involves carefully overlapping it with shingles or roofing materials to ensure water flows correctly. The flashing is bent or shaped to sit snugly against both the vertical structure (like a chimney) and the roof surface. Sealants or fasteners are used to secure it in place.

4.2 Key Principles of Proper Installation

- Overlap is critical – Flashing must always be installed in a way that overlaps roofing materials, never underneath them.

- Slope matters – The flashing should direct water downward and outward, never allowing it to run back toward the structure.

- Tight seal – Gaps must be sealed to prevent wind-driven rain from sneaking behind the flashing.

- Compatibility with roofing – The flashing must integrate with shingles, tiles, or metal roofing for a watertight finish.

4.3 DIY vs. Professional Installation

While small repairs might be manageable for handy homeowners, apron flashing installation is best left to professionals. Mistakes in placement or sealing often result in hidden leaks that cause long-term damage.

Chapter 5: Common Issues with Apron Flashing

Even though it’s designed to last, apron flashing can fail if not maintained. Some common problems include:

- Rust and corrosion – Especially in steel flashing that hasn’t been properly coated.

- Sealant failure – Over time, caulking or roofing cement may crack or wear away.

- Improper installation – Incorrect overlaps or gaps can cause leaks immediately.

- Damage during roof repairs – Flashing can sometimes be bent or dislodged when shingles are replaced.

Chapter 6: Maintenance Tips

Keeping apron flashing in good condition doesn’t require much effort, but regular inspections help.

- Check after heavy storms – Look for signs of displacement or damage.

- Clean debris – Leaves and dirt around chimneys and dormers can trap moisture.

- Inspect for rust – Spot-treat minor corrosion or consider replacement if damage is extensive.

- Reapply sealant – If caulking looks cracked or dry, replace it to maintain a watertight seal.

Chapter 7: Comparing Apron Flashing with Other Flashing Types

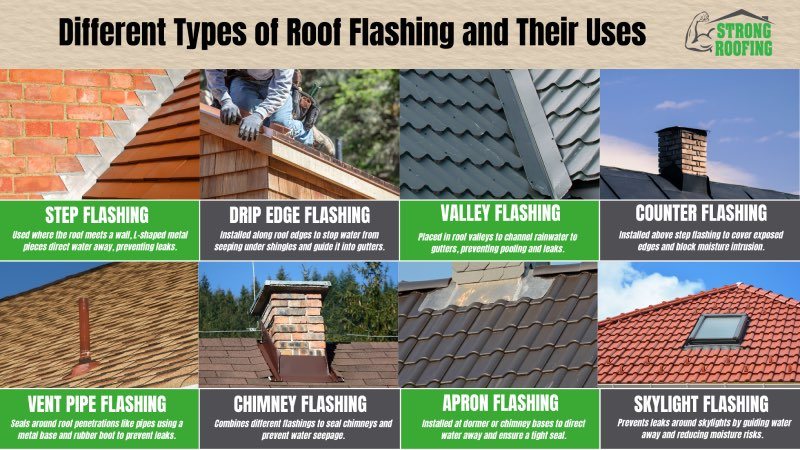

Roof flashing comes in several forms, and apron flashing is just one of them. Here’s how it compares:

- Step Flashing – Used along sloped roof-to-wall intersections, installed in overlapping layers with shingles.

- Counter Flashing – Installed over apron flashing, particularly around chimneys, for added protection.

- Valley Flashing – Runs down the “valleys” where two roof slopes meet.

- Drip Edge Flashing – Installed along the roof edges to direct water into gutters.

Apron flashing specifically covers the bottom areas of vertical penetrations, making it unique in its purpose.

Chapter 8: Signs That Apron Flashing Needs Replacement

8.1 Interior Water Damage

Water stains, peeling paint, or musty odors near chimneys or dormers may indicate flashing problems.

8.2 Visible Rust or Cracks

If the flashing itself looks worn, dented, or rusted through, it’s time for replacement.

8.3 Missing Pieces

In some cases, flashing can be dislodged by strong winds or improper repairs. Missing sections must be replaced immediately.

Chapter 9: Cost Considerations

9.1 Material Costs

- Steel flashing is usually the most budget-friendly.

- Copper flashing can cost several times more but may last a lifetime.

9.2 Installation Costs

Labor costs depend on roof accessibility, pitch, and the complexity of the job. Replacing flashing around a chimney often costs more than installing it on a simple dormer.

9.3 Long-Term Value

While upfront costs vary, good apron flashing prevents expensive water damage, saving money in the long run.

Chapter 10: Real-Life Scenarios

Imagine a home with a chimney in the middle of the roof. Without apron flashing, rainwater would run straight into the seam at the base of the chimney, leaking into the attic and damaging insulation. With apron flashing properly installed, water is directed away and safely shed onto the roof surface.

Another example is a dormer window. Without flashing, the lower joint where the dormer meets the roof would trap water and eventually rot the wood. Apron flashing protects this vulnerable area, extending the life of both the dormer and the roof.

Chapter 11: The Future of Apron Flashing

Roofing technology continues to evolve, and apron flashing is no exception. Some future trends include:

- Coated metals that resist corrosion even longer.

- Prefabricated flashing kits designed for easier, error-free installation.

- Integrated systems that combine flashing with ventilation or insulation components.

These innovations aim to make flashing more durable, efficient, and user-friendly.

Chapter 12: Frequently Asked Questions

Q: Can apron flashing be reused when replacing a roof?

Sometimes, if it’s in excellent condition, but usually new flashing is recommended for maximum protection.

Q: How long does apron flashing last?

Depending on the material, anywhere from 15 years (for basic steel) to over 50 years (for copper).

Q: Can you paint apron flashing?

Yes, many homeowners paint flashing to match their roof or siding, though it’s important to use paint that adheres to metal.

Q: What’s the difference between apron flashing and counter flashing?

Apron flashing goes at the base of vertical structures, while counter flashing is installed above it to cover the upper edge, especially on chimneys.

Conclusion

So, what is apron flashing? It’s a vital roofing component that protects the vulnerable transition areas where a roof meets vertical walls, chimneys, and dormers. Made from durable materials like steel, aluminum, or copper, apron flashing ensures water is directed away from seams and gaps, safeguarding your roof and your home’s interior.

Without proper apron flashing, water can easily find its way inside, leading to costly repairs and long-term damage. But with the right installation, materials, and maintenance, apron flashing can last for decades, providing peace of mind and reliable protection.

If you’re planning roof work or noticing leaks near a chimney or wall, don’t overlook apron flashing. It may be a small part of the roof system, but its role is essential in keeping your home safe, dry, and structurally sound. 440-235-3124

(440) 307-2060

(440) 307-2060